- Sorry, this product cannot be purchased.

M10-2/4 Recirculating System

$2,330.00 – $3,540.00

Recirculation System

- 4 Stage Filtering Process

- 100% air-operated system

- Trigger Operated Flow Thru Brush

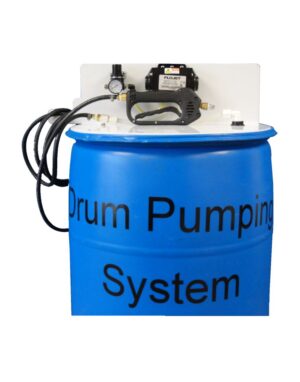

M10-2/4 Recirculating Systems

Do you hate seeing your money go down the drain after cleaning ink from your screen? Ever thought of using a recirculating system for ink removal?

Our M10-2/4 Recirculating Systems will eliminate wasting chemicals every time you clean ink off the screen. The M10-2/4 is designed to fit under our RhinoTech Washout Booths. Once in place it operates with a pneumatic pump to pump screen wash through a brush back onto your screen, thus recirculating the chemical. This will save you hundreds of dollars from being wasted.

Features:

- Chemical Resistant Polypropylene Construction

- 4 Stage Filtering Process

- 100% air-operated system

- Trigger Operated Flow Thru Brush

- Reduces solvent consumption up to 80% which means less waste going down the drain.

- Small Foot Print Size (24″x31″x19″)

Choose from these models to fit your needs:

- M10-2 – Recirculating Pumping System, Air Operated Trigger Action, Flow-Through Brush, 2 GPM Pump & Flow Tray, Filtration Media

- M10-4 – Heavy Duty Recirculating, Pumping System with Air Operated 4 GPM, Pump & Flow Tray Filtration Media

Operating instructions:

- Install Filter paper on back of unit and feed through the above slot.

- Insert filter cartridge into housing and tighten with wrench provided.

- Place the M10-2 under the drain on the washout booth.

- You can either pre-fill the M10-2 before sliding it in place or fill it through the washout booth drain. You will want to fill the unit with 15 gallons of screen wash.

- Plug in the air and turn the green lever to on. Turn the air pressure up to 60 psi.

- Put the brush into the booth and pull the trigger. The system should fill up with chemical and begin to flow through the brush. Release the trigger and the unit should stop running.

Troubleshooting:

- If the pump continues to operate, check the various fitting for air leaks and tighten. Do Not Overtighten.

- No Liquid being Pumped through Brush: Check for debris clogged in inlet fitting attached to tank and hoses connecting to the pump. Replace the canister filter.

[youtube-embed]https://www.youtube.com/embed/ideux4F_fYc?rel=0[/youtube-embed]

| Model-Recirculation | M10-2: 2 GPM, M10-4: 4 GPM |

|---|